What is laminar flow and how does it affect my range hood?

Have you heard of the principle of laminar flow? It’s often used in physics to describe the movement of water through duct systems.

But did you know that it also applies to range hoods?

Learn all about laminar flow and how it applies to range hoods in this article.

Table of Contents

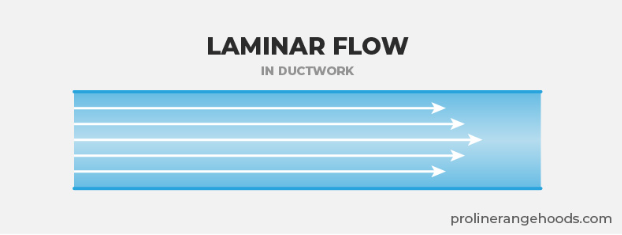

What is laminar flow?

Laminar flow is the flow of air or fluid with little to no resistance. The air moves parallel in one direction to keep it moving efficiently.

A hood designed with laminar flow in mind is highly efficient. It moves all your greasy kitchen air out of your home with ease.

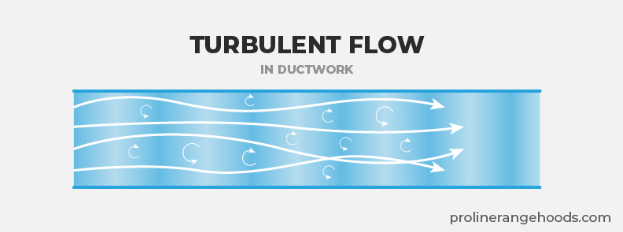

What is turbulent flow?

Turbulent flow is the flow of air or fluid through a duct with heavy resistance. The air twists and turns, slowing its movement.

Think of turbulence on an airplane. It’s chaotic. You move up and down, twisting and turning.

A range hood with turbulent flow is inefficient. It moves air chaotically. The air has difficulty making it to the outside of your home.

As a result, excess grease may accumulate in the hood and ductwork. This makes it harder for your kitchen air to get to the outside.

You probably won’t have a hood with zero turbulence.

But the best hoods are built to reduce the turbulence as much as possible to improve their efficiency.

So, here’s the million-dollar question: Can you reduce turbulence and make your whole kitchen exhaust system more efficient?

We’ll show you some ways you can and how they affect both laminar and turbulent flow.

7 Things to Consider to Make Your Hood More Efficient

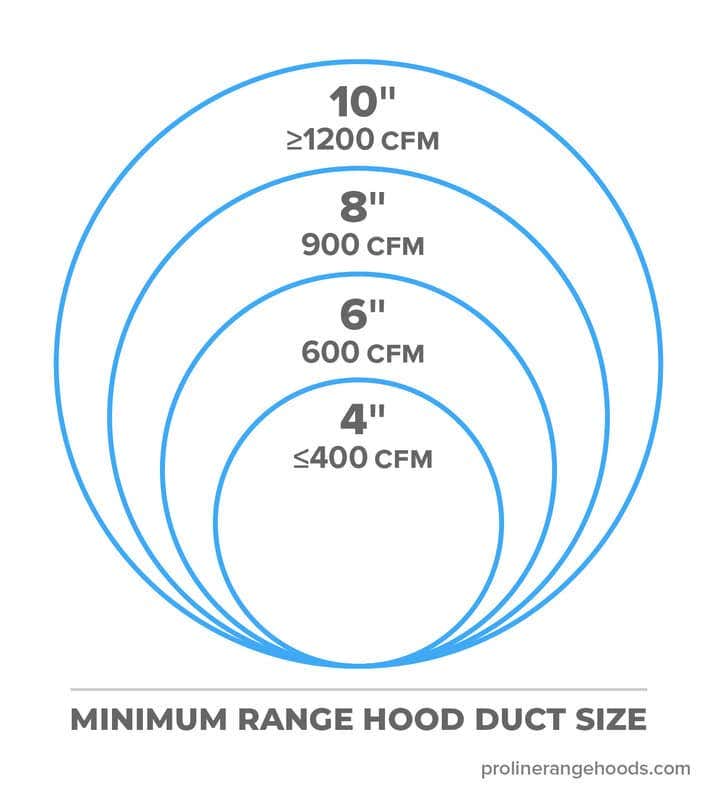

Do you have appropriately sized ductwork?

The size of your range hood duct depends on the CFM of your hood. Generally, the higher the CFM, the larger the duct you’ll need.

Meet the minimum requirements outlined in the chart above to decrease the turbulence in your duct.

Remember that you can’t go wrong with larger ductwork.

For example, it’s possible to use 8” duct on a 600 CFM hood, but don’t go below that 6” minimum.

If you already use the appropriate duct size, continue down our list.

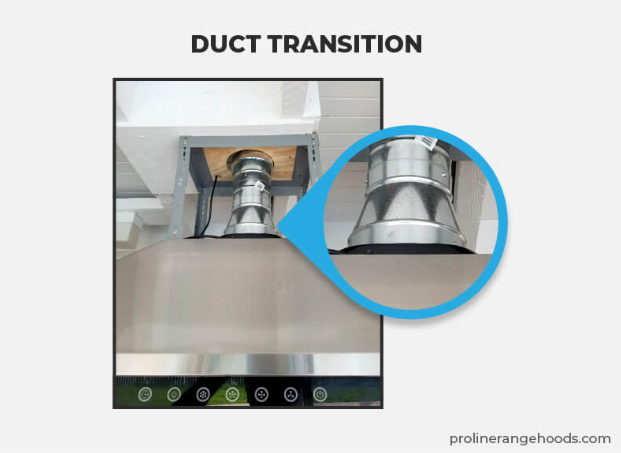

Did you use a duct transition, if necessary?

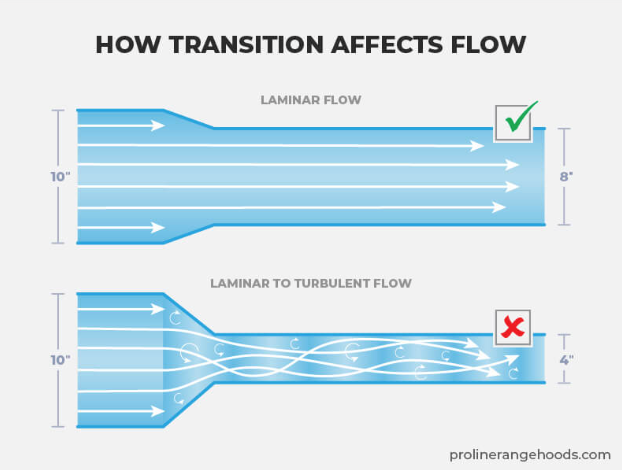

Range hoods typically use a transition piece in the picture below, to connect the ductwork to the range hood.

Depending on your setup, you might need a transition piece. This transition piece can either reduce or expand your duct.

Duct Reducer

If your ductwork is wider, the transition won’t be as steep and won’t choke the air in your duct.

Duct Expander

Another type of transition is a duct expander. If your hood for some reason doesn’t meet the minimum duct size requirements, you’ll need a duct expander.

For example, if you have a 1200 CFM hood with an 8” opening, use a duct expander to increase the duct to 10”.

Do you have to clean your filters more often than normal?

Most cooks should clean their filters every two to three months. Avid cooks should check their filters for grease every month or so.

Learn more about how to clean your range hood filters in this complete guide.

How long is your duct run?

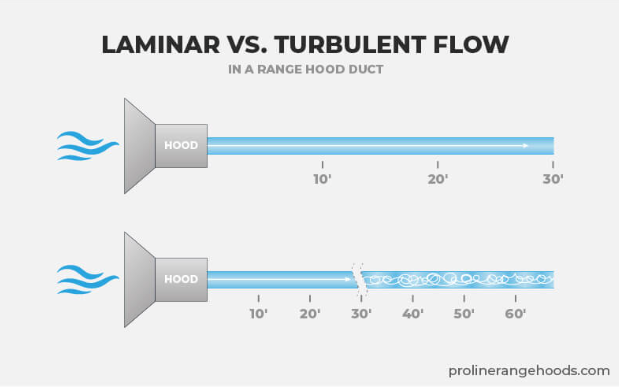

We recommend that you keep your duct run less than 30’.

The shorter you can run your duct, the better. Your kitchen air won’t have to travel as far. This will allow you to clear the cooking exhaust out of your more efficiently and effectively and create less wear and tear on your hood as well..

Your hood will also use less power to move air through the ductwork.

But, if your duct is too long you increase the chances of introducing turbulent flow.

To facilitate laminar flow, run your duct 30’ or less, illustrated in the top graphic.

To learn more about your duct run and best practices for your range hood duct, check out our comprehensive guide.

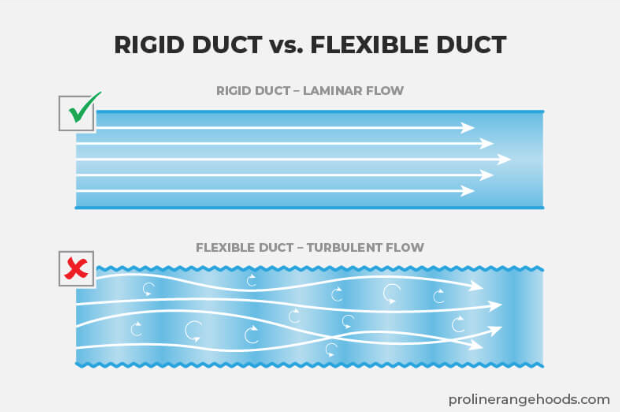

What type of ductwork do you use?

Another way to facilitate laminar flow is to use rigid ductwork. Flexible duct is made of cheaper materials and has ridges which create resistance in the duct system. This slows the flow of air, creating turbulence, and decreases the efficiency of your range hood.

But a rigid duct has no ridges which increases the efficiency of your hood.

Rigid duct lasts much longer than a flex duct, so your hood will run for years to come.

How long is your duct run before the first elbow?

There should be no less than 18” of space before the first elbow. If the first elbow is less than 18” from the hood, this adds a lot of resistance, keeping the air from moving easily.

Also, make sure there is at least 18” of ductwork between elbows if you are installing more than 1.

How many elbows do you have in your duct run?

To facilitate laminar flow, use as few elbows as possible in your ductwork. Ideally, use no elbows.

If necessary, use up to two elbows, but not more. And make sure there is at least 18” of ductwork between them.

More than two elbows introduce heavy resistance and, in turn, turbulent airflow.

Hopefully these tips will help you improve the efficiency of your range hood setup.

For more range hood tips and advice, check out the articles below.

Related Articles

Is it OK to vent a range hood into the attic?

Comments are closed.